Making any progress, you slackers? Tell us about it!

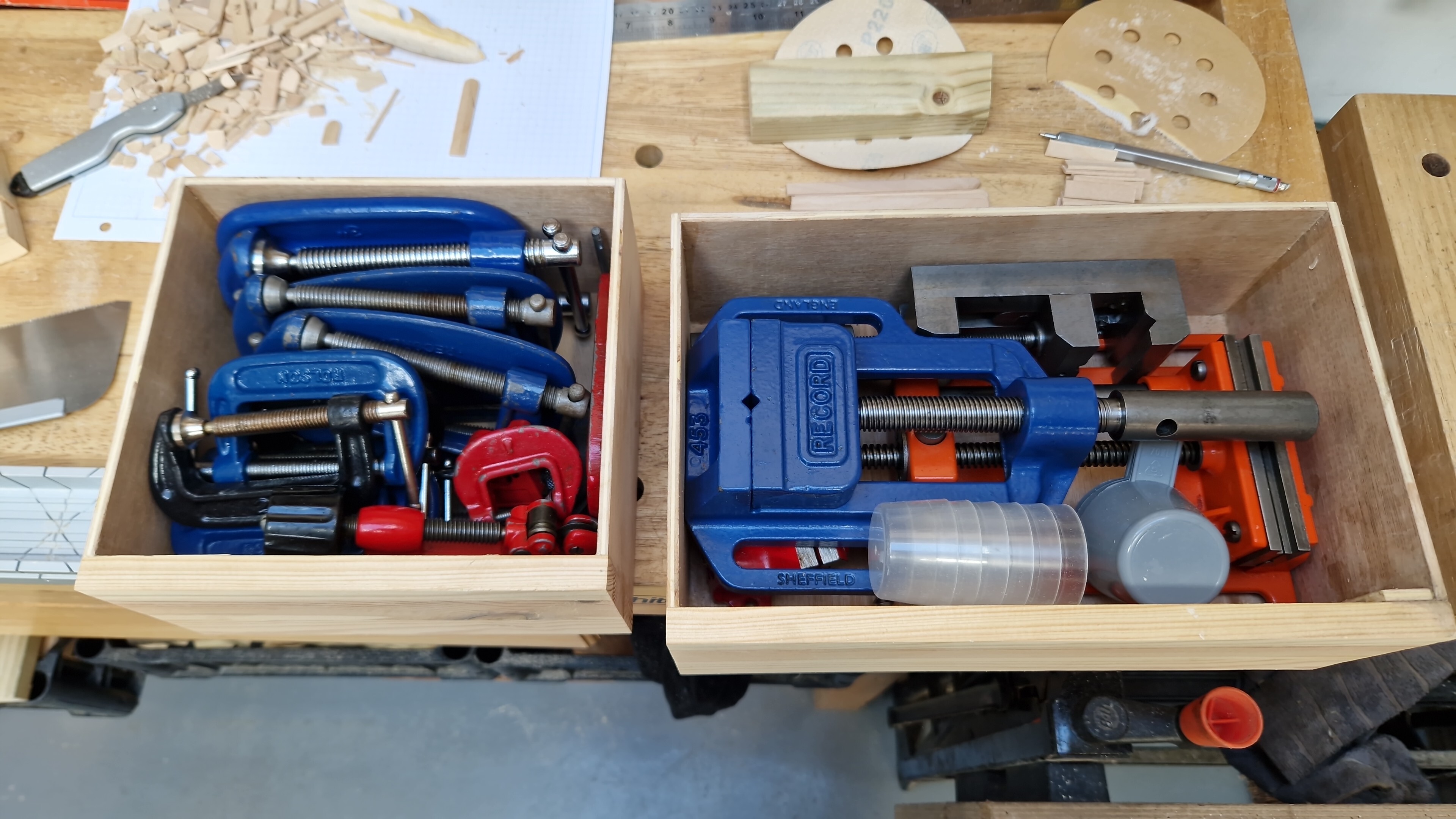

Currently putting the finishing touches on a wall-mounted chest of drawers for the workshop, which is holding everything from screws to scrap metal to machinist vices. It’s made of scrap pallet wood and ply and totally hand-tooled (planes/chisels/saws). My workshop is very very small (under 8ft by 9ft) and doubles as my home office, so this baby really frees up major space.

Just the rest of the drawer labels left to do. Not sure if these photos will work, but here goes:

Nice

though not as home oriented as most posters here, i have a denim jacket i’ve been working on for the past couple months. have been making and sewing my own patches on, and am currently looking at dyeing the sleeves, though i’ve been procrastinating from that a bit ;)

Currently stripping popcorn ceiling on entire first floor, shoring and patching dry wall on all walls and ceiling, painting entire first floor, and replacing most fixtures and rugs. May not sound like much, but it’s full time. First spruce up place has had in 21 years. Also replacing pads and rotors on car when I need to take a brake (intended) from the dust and endless sanding.

Stripping popcorn ceiling

Doesn’t sound like much

These are mutually exclusive. The best case scenario for popcorn ceiling is that it’s a tedious pain to remove, and it only gets worse from there (painted, asbestos, etc.)

My list for the month:

- Bring the drill press inside and see if I can get the rust off the base. Like the crappy hand plane I derusted a couple of weeks ago, it’s been sitting in an unheated shed through several Canadian winters and attracted condensation. It’s functional, but the table is a mess.

- Do Something with the red oak left over from the desk chair repair (since I had to buy a much longer piece than I needed for that). It will likely be combined with a piece of leftover birch plywood to become a tray, and the leftovers from that will become a wooden mallet.

- Attempt to 3D print a fairly complex router base for my Dremel, which is going to be interesting because the available instructions are 1. scant and 2. in German.

It’s not much honestly, but in order to make both kids fit in one room I’m making all their furniture from sheets of MDF. This was my very first project, and likely a mistake, but good progress has been made.

I recently made a netting needle and paracord hammock 😎

Planning to replace the old TV coax cable with Ethernet cable so everybody in the house gets their own low-latency connection for gaming. The problem is that TV cable is installed in a daisy chain while Ethernet has a star topology, and there’s only room for one cable from the basement to upstairs. So at the moment I’m pondering whether to keep the daisy chain and place a switch in every room, use some sort of MoCA (Ethernet over coax) adapter or go all the way and install fiber.

Also, we should really replace the carpet in the master bedroom with hardwood soon.

(Edit: spelling)

I’ll go ahead and say that I’m using a MoCA connection to my main PC, and have no complaints about it at all. It’s the 2.5Gbps by ScreenBeam.

Not sure how exactly that works with the daisy chain, but brief reading seems to indicate that it should be fine to add a MoCA endpoint in each room, unless you wanna just rewire the upstairs with a single switch and Ethernet cables to each room up there, assuming you have room to run all the cables in the upstairs only.

We are renovating our Atelier to be a temporary house while we strip and redo the main house. My girlfriend’s parents have done a full renovation, he is an industrial electrician, her brother is a woodworker just out of school and a modular house designer. They are all super helpful and I am so grateful and learning a lot.

During the 2 weeks I worked only 2 days per week and a few weekends before we have:

-

trash removal of previous owner

-

ripped out electrical in the main house

-

tore down the gyprock in one room and found that the main house and atelier both have a moisture blocking barrier after the first brick layer

-

washed away the gritty loam paint that the previous owner had used over much of the house

-

primed and painted the entire 44m^2 atelier stone walls

-

placed 6cm cheaper insulation in the storage area since there it was only 1 brick thick instead of 2 bricks plus a space.

-

cut a hole in the brick wall for the gas heater stove

-

got a quote for switching to 3-phase 25A, 400V and prepared the site

-

made a temporary fence to keep our dog in the first piece of our garden that is closed on the sides

-

cut and dug trenches inside for gas, water, electric and internet

-

broke up and hauled away 6cm thick concrete slab where we had to route things under

-

placed and hooked up electrical in the atelier loft, storage room, and the outdoor storage shelter behind it

-

made technical drawings for electrical, gas, sewer, and water

-

found a quality 2nd hand gas stove to heat during our mild winters

-

dug out and mapped sewer and gas lines through the property

-

dug a 24 meter trench 70cm deep and laid water, gas, and 3-phase electric (in a flexible pipe) in that layer, and laid internet and sewer at ~40cm deep with a measured 1cm per meter “afwatering.”

-

Quotes for redoing the asbestos filled roof in the main house and currently setting up asbestos testing for the slanted wall since the attestation documentation seemed to be wrong and there is asbestos-based insulation according to a roofer + asbestos remover we got a quote from

-

temporarily rennovated the small bathroom, repainted, replaced the broken toilet, removed the leaky sink, and re-silicones the tiny sitting bath/shower and replaced the shower head

-

Found 30m^2 of click laminate for 40€. Proud of that find. Good condition too.

Next up is hooking up the gas and water fittings fully inside, getting a plumber to come test and hook us up to the main 22mm line to the boiler in the house, place and hook up the electrical in the kitchen/living room and for the appliances, find a 2nd hand oven, stove, and fume hood, and fill in the inside trenches and re-pour the concrete, place the floors and finish up for the year in the next month.

Wow. It sounds like you have been hitting it hard. May your work be fruitful and trips to the hardware store minimal.

-

I am currently not installing a ventilation system in the workshop to remove nasty 3d printing fumes. Any day now I will start.

Not much at the moment. Trying to find out how to the table saw fixed before I can actually do something useful.

I have many projects going on.

-

Complete window / frame restauration underway at the country house built in the fifties, I scraped all the original paint off by hand and now I’m waiting for drier days to finish the painting.

-

Fixing the terrace at the country house, I laid the first new layer of concrete to fix the corroded parts just last Thursday. When it dries I’ll see if an entire additional layer is required. Next summer I’ll also rebuild the terrace fence and install growth lines for vines over the terrace.

-

Acoustic Research AR-7x speaker restauration. I installed the new woofer surrounds few weeks ago, now I’m waiting for the ferrofluid for the tweeters to arrive by mail. Just yesterday I found suitable and cheap linen cloth for the new covers in a nearby cloth shop.

-

Fixing the rain gutters at home, the weight of last winter’s snow and ice pulled some if the screws off. This is a priority.

-

Yard fence repainting, I rebuilt a large part of the fence in June but the weather has been too hot / humid to paint the old parts.

-

New ceiling curtain rail installation at home. Would be easy per se, but it’s a two man job and the ceiling is high…

-

Motorcycle needs a new heat resistant paint job for the exhaust.

-

Two sets of new custom speaker stand parts are cut and ready for welding, just haven’t had the time to start it yet.

…and many more.

-

I just installed 12" exhaust fan in my garage because my car refuses to charge it’s so hot. 15 minutes to install and wire the fan. 2 days to frame and finish both sides. I fucking hate stucco.

I finally managed to make my coffee table into an usable state but it still needs a bit more wood to become stable and then it needs to be waxed/oiled.

Got a cabinet in similar state: got the doors cut, fitted and filled, just need the hinges. But the doors will stay if you lean them and maybe a little wedge. They’ve been like that since July. 2002.

I turned a ring “box” on a lathe and my fiancée said “yes!”

Just moved into a new place, so a lot of things: -Building a compost bin

-Hanging shelves, mirrors, paintings, etc.

-Installing new electrical outlets

-Adjusting doors that are out of alignment

-Reupholstering a few chairs